Amazing Live Video of BP Oil Spill Sealing Efforts (BP Oil Spill Live Feed)

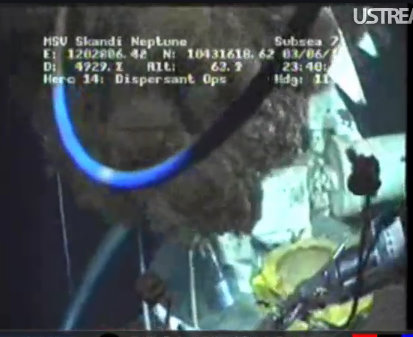

The live video of the BP oil spill is pretty amazing at the moment because it appears to be showing BP’s new seal being placed over top of the gushing oil pipe. Early today, BP announced that the saw blade that was caught in the oil pipe had finally be fixed, and the pipe was cut so the seal can be moved into place.

Now, looking at the video, it appears that the seal is being maneuvered over the gushing BP oil pipe, and because of the live video feed, you can watch this procedure take place 5000 feet deep in the Gulf of Mexico in real time.

Even though it appears that there is a seal in place, oil continues to gush out of the busted pipe. Earlier I wrote about how some of the gushing oil looks to be channeled through a pipe. This looks like BP is preparing the system of pipes to actually channel the gushing oil along up to barges where the oil can be captured, stored, and reserved.

Here’s the new BP live oil spill feed:

2 replies on “Amazing Live Video of BP Oil Spill Sealing Efforts (BP Oil Spill Live Feed)”

The flow of oil in the Gulf could be stopped in just a few days.

The riser that was cut is attached to the BOP with a bolted flange. There may be a drill stem in the hole (I understand that the drill stem is what jammed the diamond wire saw). This is the process. 1) Cut the bolts holding the flange. A circular saw can be used because it is not going to get into the flow. Remove the flange. 2)If there is a drill stem, get hold of it (the drilling company can fish it out – they know how) and bring the top end to the surface. This requires a drill ship but that is no problem as there are two on site. The first section of the drill stem will be damaged but it just threads off and can be replaced. The whole drill stem does not have to be removed because we need it in the hole. 3) Run a string of drill stem pipe to the bottom of the hole. 4) Pump heavy mud down the drill string. This will kill the well. The situation described here is exactly what they are attempting to do with the relief well. When the relief well is completed it will just be a hole with a drill stem inside and they are going to pump mud down that drill stem. All that prevents them from doing this today is that mangled flange on top of the Blow-Out-Preventer.

This is a feasible solution to the leak. It is exactly the same as the bottom-kill process using a relief well. In one case there is a hole beside a hole and they meet at the bottom and in the second case there is a hole inside a hole and they meet at the bottom. From a flow and pressure perspective, these are identical cases. It has a 100% chance of success and it can be done in two or three days with equipment and people already on site in the gulf.

Tom Walton

Professional Engineer

The flow of oil in the Gulf could be stopped in just a few days.

The riser that was cut is attached to the BOP with a bolted flange. There may be a drill stem in the hole (I understand that the drill stem is what jammed the diamond wire saw). This is the process. 1) Cut the bolts holding the flange. A circular saw can be used because it is not going to get into the flow. Remove the flange. 2)If there is a drill stem, get hold of it (the drilling company can fish it out – they know how) and bring the top end to the surface. This requires a drill ship but that is no problem as there are two on site. The first section of the drill stem will be damaged but it just threads off and can be replaced. The whole drill stem does not have to be removed because we need it in the hole. 3) Run a string of drill stem pipe to the bottom of the hole. 4) Pump heavy mud down the drill string. This will kill the well. The situation described here is exactly what they are attempting to do with the relief well. When the relief well is completed it will just be a hole with a drill stem inside and they are going to pump mud down that drill stem. All that prevents them from doing this today is that mangled flange on top of the Blow-Out-Preventer.

This is a feasible solution to the leak. It is exactly the same as the bottom-kill process using a relief well. In one case there is a hole beside a hole and they meet at the bottom and in the second case there is a hole inside a hole and they meet at the bottom. From a flow and pressure perspective, these are identical cases. It has a 100% chance of success and it can be done in two or three days with equipment and people already on site in the gulf.

Tom Walton

Professional Engineer